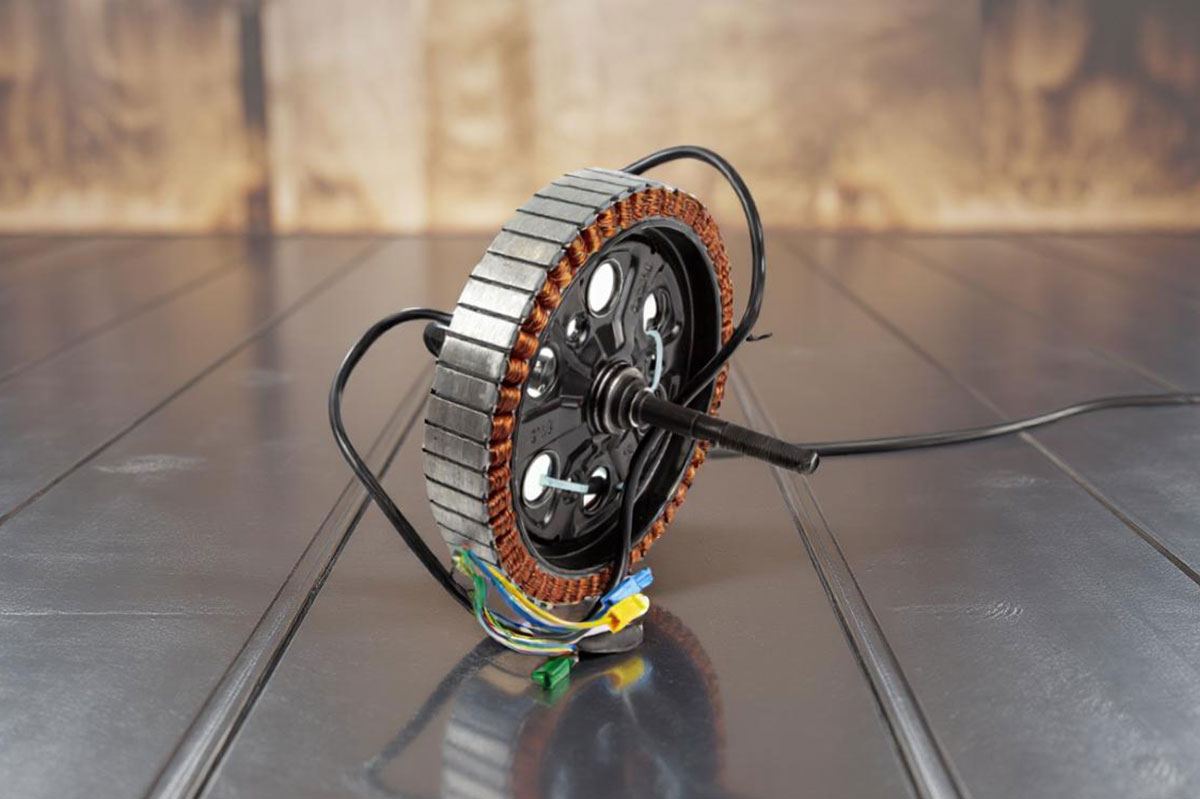

Coil Rewinding

Restore damaged windings:

- Accurate wire gauge specs

- RR Kabel copper wire

- Prevent overheating/short circuits

Coil rewinding is a critical process in maintaining the performance and longevity of both hub motors and mid-drive motors, which are often exposed to constant vibrations and harsh environmental conditions. Over time, these stresses can wear off the enamel coating on copper windings, leading to overheating and eventual short circuits. At SEB, we follow a well-defined rewinding protocol that ensures reliable performance. This includes accurately identifying the correct wire gauge, determining the number of strands, calculating the number of windings, and setting the proper coil direction. To ensure durability and efficiency, we exclusively use branded copper wire from RR Kabel for all our rewinding work.